⠀

⠀

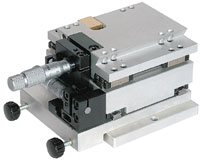

ESC-COMEC KP16

Printing sizes of up to 145 mm diameter are considered as large-format in pad printing.

The ESC-COMEC KP16 pad printing machine fulfills requirements owing to its special internal construction and assures long-term smooth operation and precision.

Standard features:

- closed ink cup system reduces ink consumption by 50 % and eliminates solvent odours

- high-quality, low-wear ceramic ring

- silent pneumatic precision drive

- touch screen console for freely programmable machine functions

- micrometric fine adjustment in x-y-z-direction with ± 15° rotation possibility at the cross table as well as ± 10° rotation possibility at the printing unit

- pad holders adjustable in height

- prepared to be connected to all optional feeding systems and optional equipment

- prepared to be integrated into existing production lines

- single operation for setup mode

- single mode with operation via foot pedal or automatic mode

Optional extras:

- individually lowerable pads (model TI)

- automatic pad cleaning station

- rotary printing device AUR-360

- flaming station

- Corona unit

- Hot Wind Dryer Masterflow: blowing device for multicolor printing

- automatic loading and unloading station

Optional feeding systems

pneumatically driven step-by-step feeder STEP 2 ST PN (for 2C machine) | electromechanically driven elliptical feeder ALM 12 ST P159 (4C) | electromechanically driven linear feeder ALM-LIN 20 ST (4C) | electromechanically driven rotary table T15 |

electromechanically driven step-by-step feeder STEP930 EL (4C) | electromechanically driven elliptical feeder ALM 14 ST P159 (5C) | electromechanically driven linear feeder ALM-LIN 26 ST (5C) | pneumatically driven rotary table TRP 160 and PN 250 |

electromechanically driven step-by-step feeder STEP1230 EL (5C) |

Machine versions

KP16 2C (version TI)

KP16 5C

Machine details

pad holders adjustable in height | automatic pad cleaning station (optional) |

modern, closed ink cup system | micrometrically adjustable cliché holder (optional) |

Technical data:

KP16 1-5 colors | KP16 1-color Slide | |

cliché size | 180 x 360 mm | 180 x 850 / 220 x 770 mm |

size of closed ink cups | ø 160 mm | ø 160 / 200 mm |

max. printing size | ø 145 mm | ø 145 x 550 / ø 185 x 400 mm |

horizontal pad stroke | 360 mm | |

vertical pad stroke | 125 mm | 125 mm |

max. contact pressure | 7300 N | 7300 N |

mains supply | 380 V / 50 Hz | 380 V / 50 Hz |

compressed air connection | 6 bar | 6 bar |

approx. weight | ±1200 kg | ±1000 kg |

Subject to technical modifications.