⠀

⠀

OVERVIEW ESC DRYING SYSTEMS

Not only suitable for screen printing - ESC drying technology - our innovative systems for perfect drying results.

We offer standard dryers, modular systems and individual solutions, customized for your specific needs.

Individuality - for us a matter of course. Drying is a crucial factor for the quality of your printed material. Therefore, the ESC program comprises all below shown drying systems tailored to meet your needs.

Tell us your task - you will be convinced by our solution!

//ESC-WICKET Long-term Dryer

The reliable automatic WICKET long-term is standing out for its energy-saving, eco-friendly and gentle operation. It is preferably used for material which is being processed under room temperature such as transfer paper, foils etc.https://strato-editor.com/.cm4all/widgetres.php/com.cm4all.wdn.Button/images/thumbnail.svg

The WICKET is conceived for re-circulating air operation. The entire air supply is either coming from the outside or directly from the work area. The drying air can be heated if required and after circulation is directly discharged in form of exhaust air.

Each WICKET is manufactured individually according to the customer’s specification.

Sizes and technical data on request.

//ESC-PERFECTON ’S’ Circulating Air Dryer

The new dryer generation for modern printing machines -

ESC-PERFECTON `S` - high-performance continuous-flow dryer.

Earn a MINIMUM of energy costs (EUR/kWh) as well as a MAXIMUM of surface drying rate (m²/h).

Proven technology and innovative development opens up the whole range of graphic and industrial screen printing.

We are able to construct individual dryers to your specific needs as regards belt width and number of chambers. Please contact us.

//ESC-IR-TURBO PLUS°

High-performance drying system for demanding applications in graphic and industrial screen printing - conveniently controlled via touchscreen with integrated memory for drying parameters.

Best results e.g. in EL and glass printing.

//ESC UV-Bridge Module

The compact ESC-UV-Bridge Module has been conceived for the subsequent integration into existing conventional dryer configurations. It is available in standard widths of 600 - 2000 mm with 1 or 2 lamps.

//ESC UV-Plug-in Module

In combination with the ESC-PERFECTON S high-performance continuous-flow dryer, the UV-plug in module with a length of 500 mm is preferably integrated between hot and cooling zone.

The module can also be retrofitted to an existing plant. The standard version is equipped with UV lamps in the wavelength range of 200 - 400 nm, power 120 W/cm.

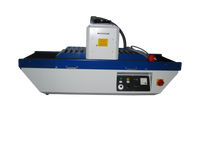

//ESC-UV-Dryer Standard

Compact stainless steel UV radiation dryer designed for the curing of printing inks, overprint varnishes, acid resist lacquers and solder masks printed on media like paper, cardboard, plastics, glass, wood, etc.

//ESC-UV-Dryer Special

UV dryer including active air cooling section, conceived to cover all requirements in UV screen printing for quick UV curing on all materials such as paper, cardboard, plastic, glass, wood, etc. It is available in standard widths of 600 - 1500 mm with 1 or 2 lamps.

//ESC-UV-Dryer Compact

This compact table-top UV-dryer assures fast hardening of UV inks and lacquers on substrates such as paper, plastic, printed boards, glass and metal.

//ESC-UV-Dryer Mini

UV radiation dryer with infinitely variable conveyor speed laid out as desktop model for quick hardening of UV inks.

//ESC-COMEC Combi-Dryer MT

Infrared and circulating air dryer (for separate or combined use) for small parts with electronic temperature control and adjustable belt speed.

//ESC-IR-Dryer Mini

The infrared dryer ESC-MINI is the universal and perfect curing system for screen printing inks on scales, panels and also on textiles.

//ESC-Horizontal-Screen Drying Cabinet

Short, uniform and dust-free drying of stencils is of utmost importance.

Our drying cabinet is entirely laid out in solid all-steel construction.

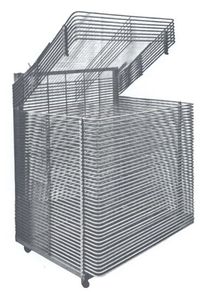

//ESC-Dryer Rack

Dryer rack in galvanized all-steel design, laid out with 25 or 50 gratings and available in different sizes. It is covered with zinc-coated, solid grid.